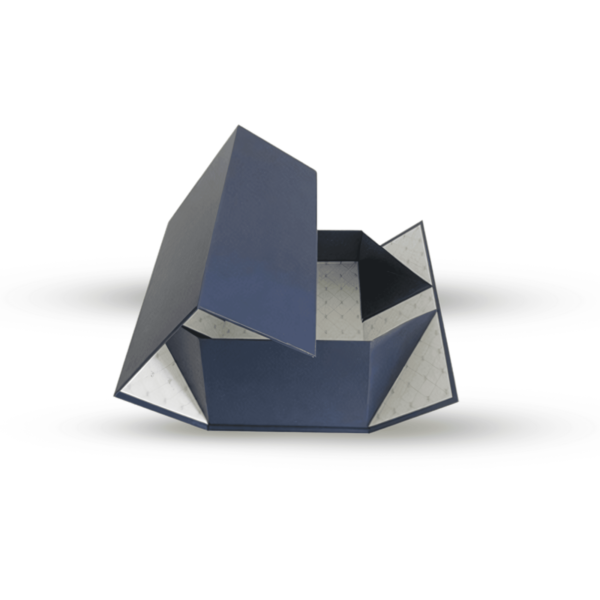

Custom Collapsible Rigid Boxes

Custom collapsible rigid boxes offer the perfect premium branding, functionality, and logistics-friendly design, making them a approved choice for businesses and brands looking to boost their product presentation. These boxes are fully customizable in terms of size, shape, material, printing, and finishing to review a brand’s unique identity.

- Estimated Delivery : 10 - 14 business days

- Free Shipping : On all Orders

Collapsible Storage Boxes – Folding Box

Our unparalleled expertise in designing and manufacturing large collapsible storage boxes with lids sets us apart from the competition. Our team of skilled professionals deeply understands the latest trends and technologies in the packaging industry.

At Custom Boxes Peak, we understand that every product is unique, so we offer various customization options for our collapsible folding storage boxes. Whether you need a specific size, shape, or design, we can create a packaging solution that meets your specifications.

Exceptional Quality – Custom Collapsible Rigid Boxes

Quality is at the forefront of everything we do at Custom Boxes Peak. We use only the finest materials and the latest manufacturing techniques to ensure that every box we produce meets the highest quality and durability standards. Our custom collapsible boxes are designed to withstand the rigors of shipping and handling while providing ample protection for your products.

Versatility and Convenience

One of the critical benefits of collapsible boxes is their versatility and convenience. Unlike traditional rigid boxes, custom collapsible boxes can be easily folded flat for storage and transportation, saving valuable space and reducing shipping costs. This makes them ideal for e-commerce businesses and retail stores looking to optimize their storage space.

Partner with Us

If you’re looking for innovative packaging solutions that combine quality, versatility, and sustainability, look no further than Custom Boxes Peak. Partner with us today and experience the difference our custom collapsible boxes can make for your business. Contact us to discuss your packaging needs and request a free quote!

Why Choose Our Collapsible Boxes?

-

Durable and high-quality materials

-

Easy to assemble and fold flat

-

Reduces storage and shipping costs

-

Completely customizable

-

Perfect for retail, gifting, and promotional use

Be the first to review “Custom Collapsible Rigid Boxes”

Most orders are shipped within 7 to 10 working days.

CustomBoxesPeak.co.uk makes every effort to ensure timely delivery. However, there may be situations beyond our control that could affect delivery times, including the following:

- Artwork issues

- Federal holidays

- Large quantities

- Force majeure

Specifications

| Dimensions | Custom Sizes |

| Material | White, Brown Kraft |

| Cardboard Thickness | 14 pt, 18 pt, 24 pt |

| Rigid Thickness | 36 pt, 48 pt |

| Color Options | CMYK, Pantone (PMS) |

| Printed Sides | Inside Only, Outside Only, Both Side |

| Finishes | Matte, Glossy, Soft Touch, Aqueous Coating, UV Coating, Spot UV |

| Add-ons | Embossing, Debossing, Die Cutting, Window Patching |

| Production Time | 8 – 10 Business Days |

| Shipping | 2 – 3 Business Days |

There are many types of glue-based inks that can be used in offset lithographic printing.

CMYK (Full Color)

Process shading, or CMYK, uses four colors: cyan, magenta, yellow, and black. These colors are combined in different amounts to create all other colors used in printing. This method is most commonly used in the packaging and printing industries.

Pantone Matching System color (PMS)

PMS color, also called Pantone Matching System color, is mainly used for printing specific spot colors. These colors are made using special inks. Each color has a Pantone number or name from a color chart, which helps ensure it looks exactly the same when printed, no matter how it appears on a computer screen.

Printing: Coating

Print coating makes your product look better and last longer. It is added to protect the product or give it a nice visual effect.

Aqueous Coating

Aqueous coating is a clear, fast-drying, water-based coating used to protect printed materials. It adds a shiny, glossy, or matte finish that helps resist dirt and fingerprints. This coating makes items like postcards, business cards, folders, and catalogs more durable—especially during mailing or everyday use. It also offers better scuff-resistance than standard varnish.

Glossy UV Coating

Glossy UV is a high-gloss, strong coating that makes printed pieces look bold and eye-catching. It brings out bright colors and adds a premium shine. This coating is great for making photos, logos, or special offers stand out, though it may be too shiny for some uses.

Matte UV Coating

Matte UV gives the print a smooth, flat finish without any shine. It adds a soft, luxurious feel and is often used for products like cosmetics or jewelry packaging where a subtle, elegant look is preferred.

Soft-Touch Coating

Soft-touch coating gives printed pieces a smooth, velvety feel. It creates a gentle texture that encourages touch and feels high-end. It’s fast-drying, environmentally friendly, and doesn’t affect print color or quality. This coating is perfect for making packaging stand out in a subtle, classy way.

Additional Information

Additional Cut-Outs

Extra cuts, shapes, or openings can be added to any custom box design to match specific measurements or create unique looks.

Window Patching

Window patching adds a clear plastic film to a cut-out area on the box. It lets part of the product show through while keeping it protected and clean. This is a great way to give customers a sneak peek at what’s inside without opening the package.

Embossing

Embossing raises a design or text above the surface of the box, creating a 3D effect you can see and feel.

Debossing

Debossing is the opposite of embossing. It presses the design or text into the surface of the box, creating an indented effect.

Foil Stamping

Foil stamping uses heat and pressure to apply a thin metallic foil—usually gold or silver—onto paper or packaging. A heated metal die presses the foil onto the surface, leaving a shiny and eye-catching design.

Perforation

Perforation is the process of making small holes in a material to make it easier to tear or remove a part. For example, a flap on a box might have perforation along the edge so it can be easily torn off without damaging the rest of the box.

Reviews

There are no reviews yet.